|

|

Construction principle of three-phase torque motor

When the load increases, the motor's speed can be automatically reduced, and the output torque increases, keeping  the load balanced. The torque motor has a high blocking torque and a small blocking current, and can withstand a certain period of stalling operation. Due to the high rotor resistance and large loss, the heat generated is also large, especially at low speed and stalled. Therefore, the motor is equipped with a separate axial fan or blower on the rear end cover, forced cooling and cooling. The moment motor is equipped with a control device to regulate the voltage. The characteristics of the torque motor make it suitable for winding, stalling and speed control applications and other purposes. It is widely used in textile (de-slurry machine), wire and cable, metal processing, paper making, rubber, plastic (round wire, flat Silk, plastic bags, plastic wrap) and printing machinery and other industrial fields. the load balanced. The torque motor has a high blocking torque and a small blocking current, and can withstand a certain period of stalling operation. Due to the high rotor resistance and large loss, the heat generated is also large, especially at low speed and stalled. Therefore, the motor is equipped with a separate axial fan or blower on the rear end cover, forced cooling and cooling. The moment motor is equipped with a control device to regulate the voltage. The characteristics of the torque motor make it suitable for winding, stalling and speed control applications and other purposes. It is widely used in textile (de-slurry machine), wire and cable, metal processing, paper making, rubber, plastic (round wire, flat Silk, plastic bags, plastic wrap) and printing machinery and other industrial fields.

main feature

The three-phase torque motor is characterized by soft mechanical characteristics and can be blocked. When the load torque increases, the speed can be automatically reduced, and the output torque is increased. When the load torque is a certain value, the motor terminal voltage is changed. Adjustable speed. A speed measuring device can be added to the motor shaft to cooperate with the controller. The voltage outputted by the speed measuring device is used to automatically adjust the terminal voltage of the motor compared with the voltage given by the controller. It has the characteristics of low speed, high torque, strong load capacity, fast response, good linearity of characteristics, small torque fluctuation, etc. It can directly drive the load to eliminate the reduction gear, thus improving the running accuracy of the system.

Three-phase torque motor operation

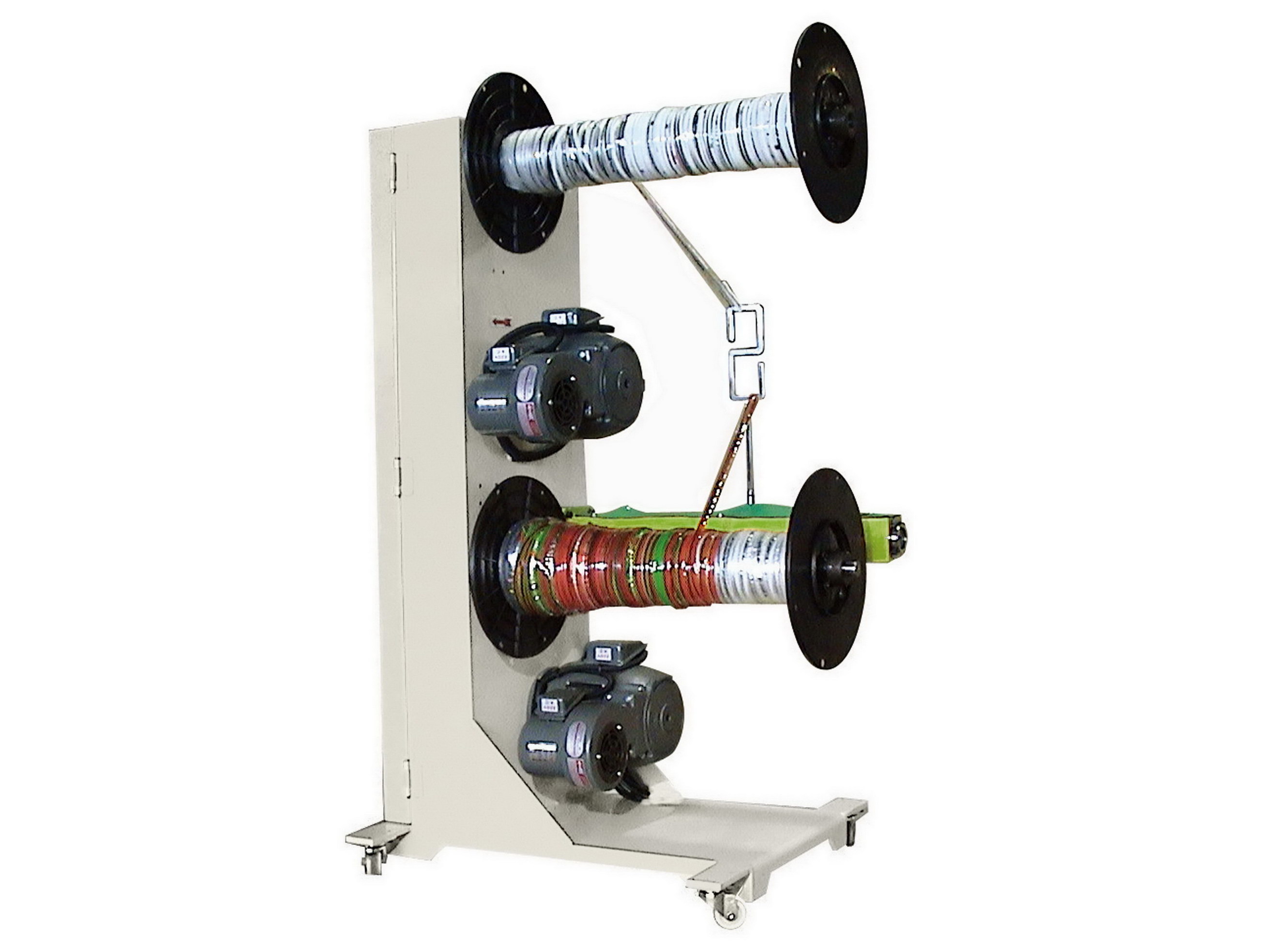

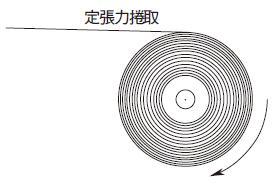

In the textile, paper, rubber, plastic, metal wire and wire and cable industries, the product needs to be wound on a reel. The diameter of the winding will increase from the beginning to the end. In order to keep the tension of the wound material uniform (ie, the linear velocity is constant), the winding speed of the reel is required to be smaller and smaller, and the winding force is increased.

1. Winding:

Winding is a very important process in wire and cable, textile, metal processing, papermaking and other processing. When the product is wound, the diameter of the reel is gradually increased, and it is important to keep the tension of the rolled product in the whole process, because the tension is too large, the wire diameter of the wire is thinned or even broken, or the thickness of the product is uneven. If the tension is too small, the winding can be relaxed. In order to maintain the tension during the winding process, the output torque of the motor that drives the reel must be increased as the diameter of the product wound onto the reel increases, while maintaining the winding product line speed. The speed of the reel must be reduced, and the mechanical characteristics of the torque motor just meet this requirement.

2. Release and unwind

In industrial production, it is sometimes necessary to transport the product wound on the drum to the next process. During the conveying process, it is required to apply a tension to the product in the opposite direction of the transmission, and at the same time, it is required to keep the linear speed and the reverse tension of the product transmission constant as the diameter of the cylinder changes, which requires the motor to have a constant braking characteristic.

3. No step speed regulation

The mechanical characteristics of the three-phase torque motor are very soft. When the load increases, the motor speed decreases, the output torque increases, and the output torque is proportional to the square of the voltage. If the load is fixed, the speed of the motor will change with the voltage change. Therefore, in a device with a constant load, any speed can be obtained by changing the input voltage of the motor through the voltage regulating device. However, when the torque motor is running at a low speed, its efficiency is extremely low, which is not conducive to long-term low-speed operation.

Blocking

In some special occasions, the motor is sometimes required to maintain a static torque for a period of time, such as tensioning at the beginning of the cable winding; forging clamps of large forging presses. Because the torque of the torque motor is large; its stall current is small, and forced ventilation is used, so it can meet the stall requirement within a certain period of time. The allowable stall time should be calibrated according to the nameplate. If a longer stall time is required, a larger torque motor can be used to obtain the torque of the torque motor.

5. Other

The three-phase torque motor can also be flexibly applied according to its various characteristics, such as its own DC series motor characteristics, which can partially replace the DC motor; and according to its rotor with high resistance characteristics, the starting (blocking) torque is large. Therefore, it can be applied to the opening and closing gate (valve) door and the drag system with large resistance torque; it can also use its starting (blocking) torque, the starting (blocking) current is small, and the mechanical strength of the solid rotor is high. |

|